Supports customizable printing templates with automatic label printing and built-in material label error-prevention mechanisms.

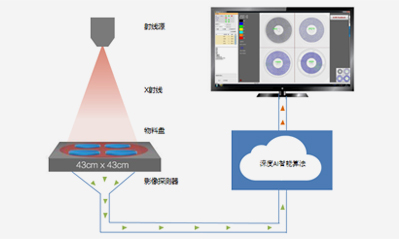

XC1000 is a micro-focus X-ray full-automatic counting machine.

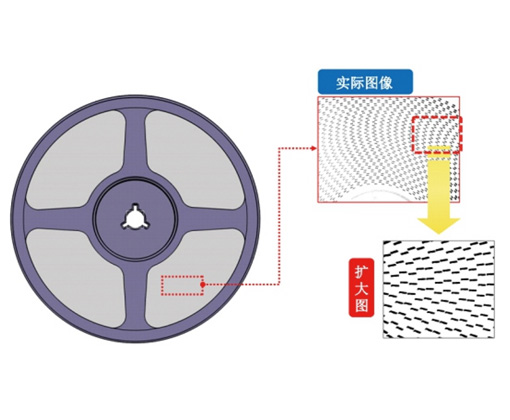

It uses X-Ray perspective principle and independently developed algorithm software with AI function, which can quickly and accurately calculate the number of materials in the material reel. This X-Ray chip counter also has MES Data upload and automatic printing of material labels. To achieve the function of improving work efficiency and saving manpower.

As a professional X-Ray reel counter supplier, Seamark trys our best to provide good products and service for you.

Suitable for a wide range of surface-mount components, including SMD devices from 01005 and above. Supports 7–15 inch reels, trays, loose components, and IC moisture-sensitive packaging, among others.

Powered by AI-based intelligent counting algorithms, enabling fast and accurate counting with precision of up to 99.99%.

Includes approximately 120,000 component records. Cloud-based collection of counting image data for newly introduced components worldwide, with weekly updates to the AI counting models.

Supports customizable printing templates with automatic label printing and built-in material label error-prevention mechanisms.

| Model | XC1000 | |

|---|---|---|

| X-Ray Tube | Type | Reflection-sealed micro-focus X-ray source |

| Tube Voltage Range | 30-80KV | |

| Tube Current Range | 200-700μA | |

| Maximum Output Power | 56W | |

| Micro-focus Spot Size | 33μm/100μm | |

| Flat Panel Detector | Type | Amorphous silicon flat panel detector |

| Pixel Matrix | 3072×3072 | |

| Field of View (FOV) | 427mm×427mm | |

| Resolution | 3.6Lp/mm | |

| A/D Conversion | 16bits | |

| Equipment Specifications | Reel Size | 7”-15”Tape Reel |

| Reel Height | 5-80mm | |

| Minimum Component Size | 01005 | |

| System Integration | MES / ERP / WMS supported | |

| Label Printing | TSC industrial printer | |

| Input Power | 220V 10A 50-60HZ | |

| Control System | Industrial PC, Windows 10 (64-bit) | |

| Dimensions | L800mmxW1280mmxH2200mm | |

| Net Weight | 790KG |

An SMD rework station is a specialized bench tool used to remove, repair, and reinstall surface-mount devices (SMDs) on printed circuit boards. It combines precision hot-air heating, controlled temperature profiles, and fine-tip hand tools to safely desolder and reflow components without damaging nearby parts or the PCB. Surface mount rework station is essential for prototyping, small-batch repairs, and quality control in electronics manufacturing.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru