In the era of 5G infrastructure and high-performance computing (HPC), the margin for error in PCB rework is virtually zero. For Top-tier EMS providers like Celestica and other industry leaders (such as Scanfil), a BGA rework station is not just a heating tool—it is a precision instrument for yield management.

While ordinary rework stations rely on open-loop heating, Seamark ZM’s industrial solutions utilize advanced closed-loop control and optical alignment to guarantee process consistency for the most complex components, including POP, QFN, and large-scale Server Boards.

The biggest challenge in reworking large thermal mass boards (such as server motherboards) is warpage and thermal shock. Ordinary "Time-Temperature" settings cannot compensate for external variables.

Seamark ZM systems (such as the flagship ZM-R9100 Intelligent Rework Station) solve this with a 3-Zone Independent Heating System:

Top & Bottom Hot Air: Provides focused convective heating for the component.

Large Area Infrared (IR) Preheating: The bottom IR panel uniformly heats the entire PCB to prevent deformation.

Most importantly, we use High-Precision K-Type Thermocouples with a PID algorithm that monitors temperature 50+ times per second. This creates a Closed-Loop System that automatically adjusts power output to maintain accuracy within ±1°C.

As shown in the curve above, the system prevents "overshoot" (damaging the chip) and "cold solder" (weak joints), ensuring the reflow profile matches the original manufacturing standard (IPC-7095).

As components shrink, manual alignment becomes obsolete. When dealing with high-density placements found in medical or industrial control products, relying on the naked eye is a risk to quality.

Seamark ZM integrates a High-Definition Optical Alignment System:

Split-Vision Technology: Our prism system allows operators to view the PCB pads (silver) and the component BGA balls (gold) simultaneously on one screen.

X/Y/θ Micrometer Adjustment: Achieves a mechanical alignment accuracy of ±0.01mm.

Automated Placement: On advanced models, the Z-axis contains a pressure sensor to detect contact height automatically, preventing solder ball collapse.

This system ensures that even 0.3mm pitch components are placed perfectly before reflow begins, drastically reducing the need for secondary rework.

For EMS leaders, data is as important as the hardware. Traceability is required to meet automotive and medical standards.

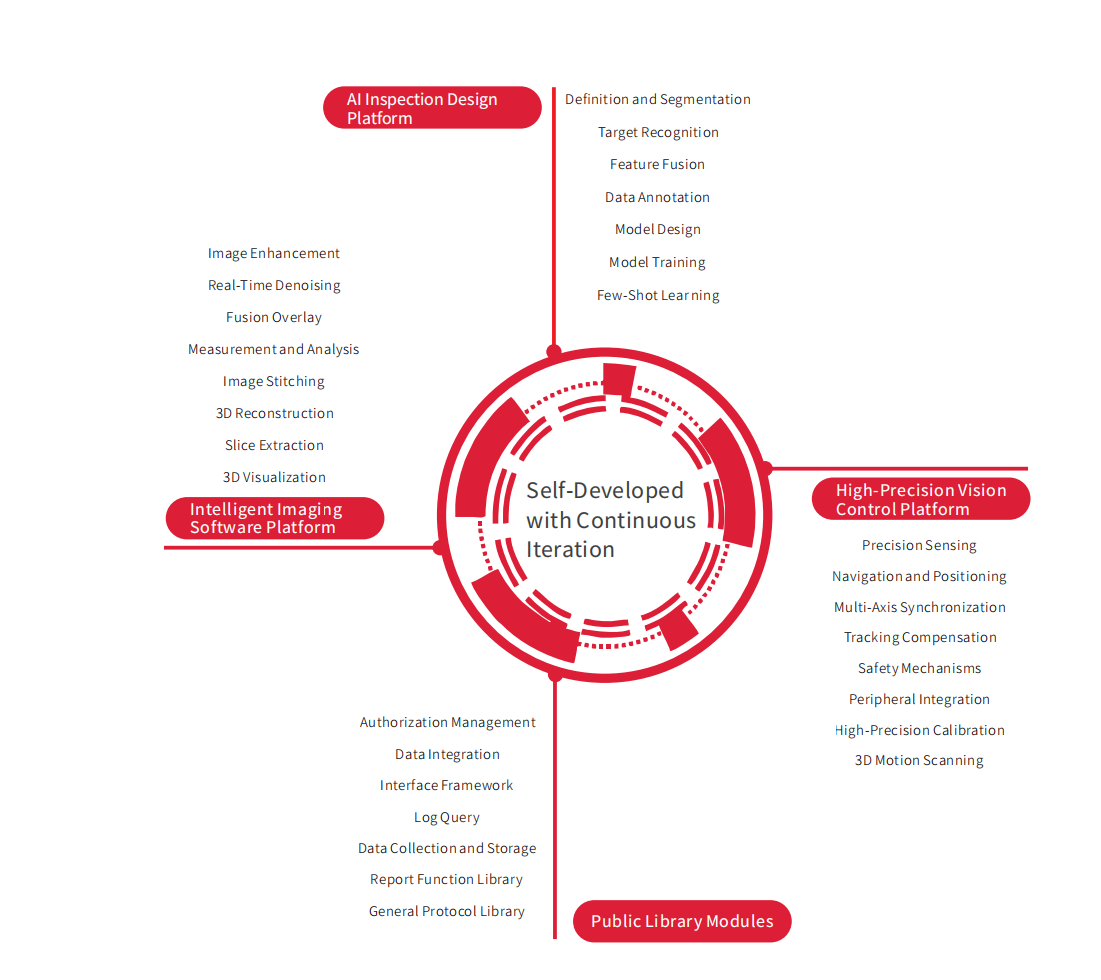

Seamark ZM’s software ecosystem is designed for the smart factory:

Automatic Profile Generation: The system can intelligently suggest temperature profiles based on chip size and PCB thickness.

MES Integration: Our equipment supports TCP/IP protocols to upload rework data (Operator ID, Temperature Curve, Result) directly to your MES (Manufacturing Execution System).

Permission Management: Multi-level login rights ensure that operators cannot accidentally change validated process parameters defined by Process Engineers (PE).

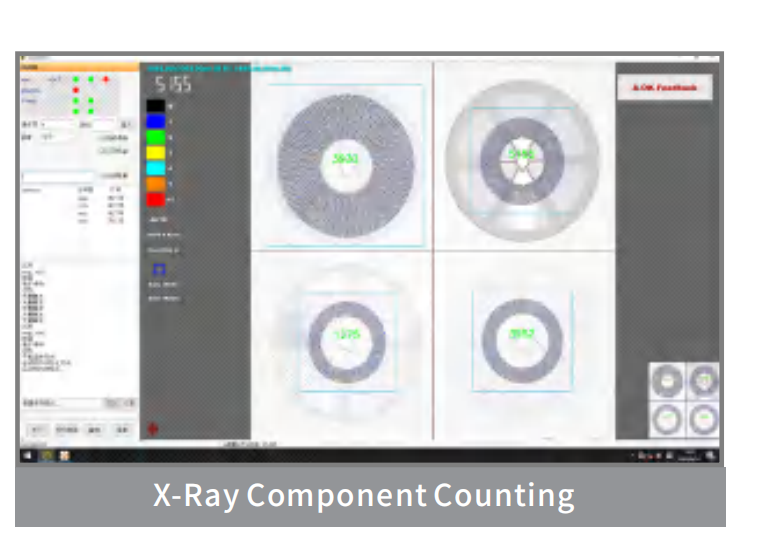

Rework is not complete until the joint quality is verified. To ensure 100% void-free soldering, we recommend pairing your rework station with Seamark ZM’s X-Ray Inspection Systems.

Our X-Ray solutions allow you to visualize:

Solder bridging (Shorts).

Insufficient reflow (Opens).

Void percentage calculation (voiding rate).

By combining high-precision rework with non-destructive testing (NDT), you create a closed quality loop that satisfies the rigorous audits of global clients.

Don't let equipment limitations compromise your production yield. Whether you are repairing 5G communication boards or critical medical electronics, Seamark ZM delivers the stability and precision required by Tier-1 EMS providers.

Ready to upgrade your rework process to the EMS Standard?

Contact us today for a customized demo for your engineering team.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru