.webp)

.webp)

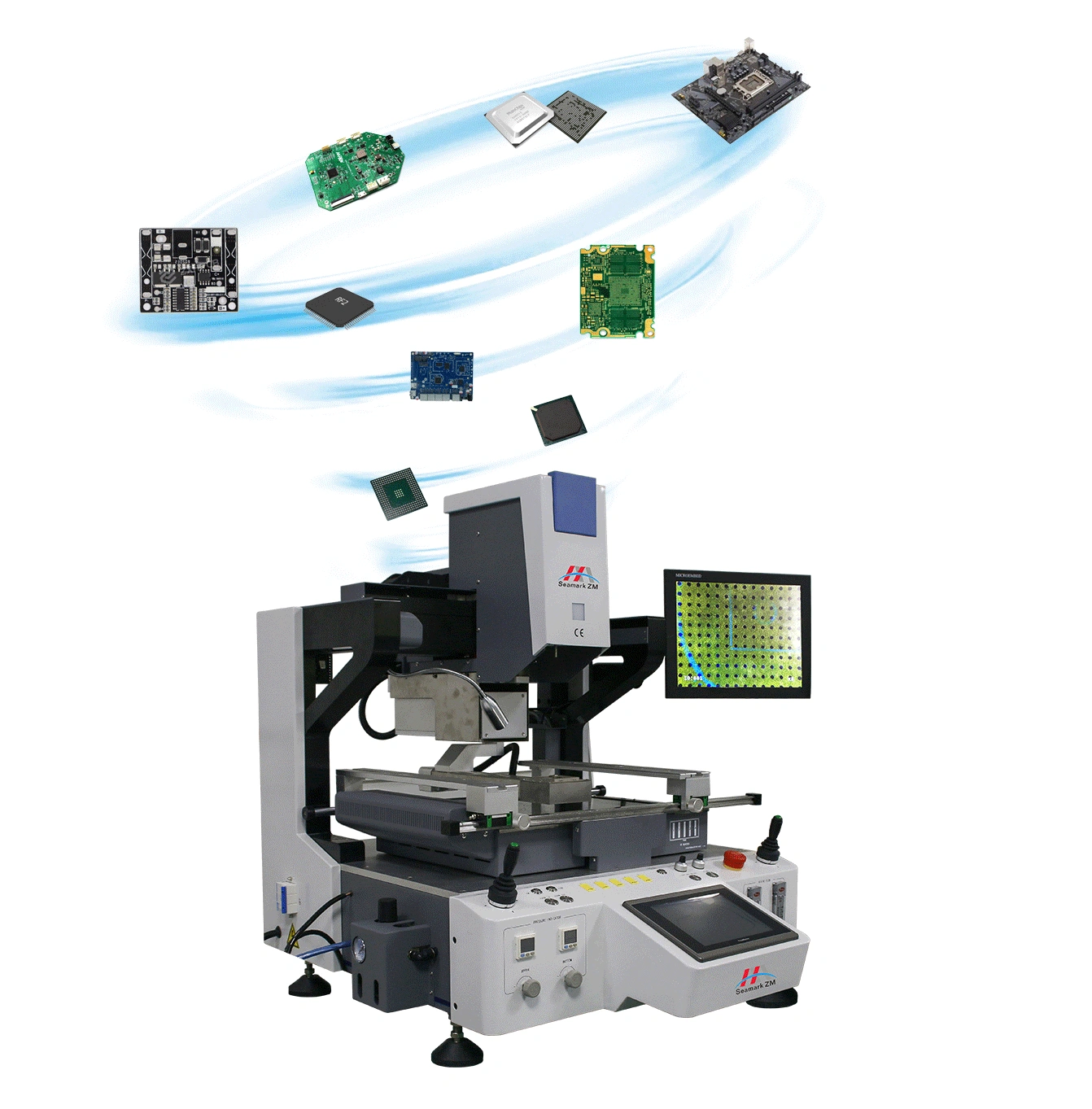

—— The Flagship Solution for High-End Server & Precision Chip Repair

The ZM-R7830A represents the pinnacle of Seamark ZM’s 2025 rework technology. This is not just a soldering tool; it is an intelligent repair center integrating Smart Temperature Control, HD Optical Alignment, and Fully Automated Operation.

Engineered to solve the most difficult rework challenges—from large-scale Server Boards and 5G Base Stations to microscopic Mobile Chips (down to 01005)—the R7830A utilizes advanced Hot Air + Infrared (IR) Hybrid Heating to ensure 99.9% success rates without damaging sensitive components.

Pro Tip: Eliminate manual alignment errors. The R7830A makes complex BGA rework a standardized, repeatable, "one-button" process.

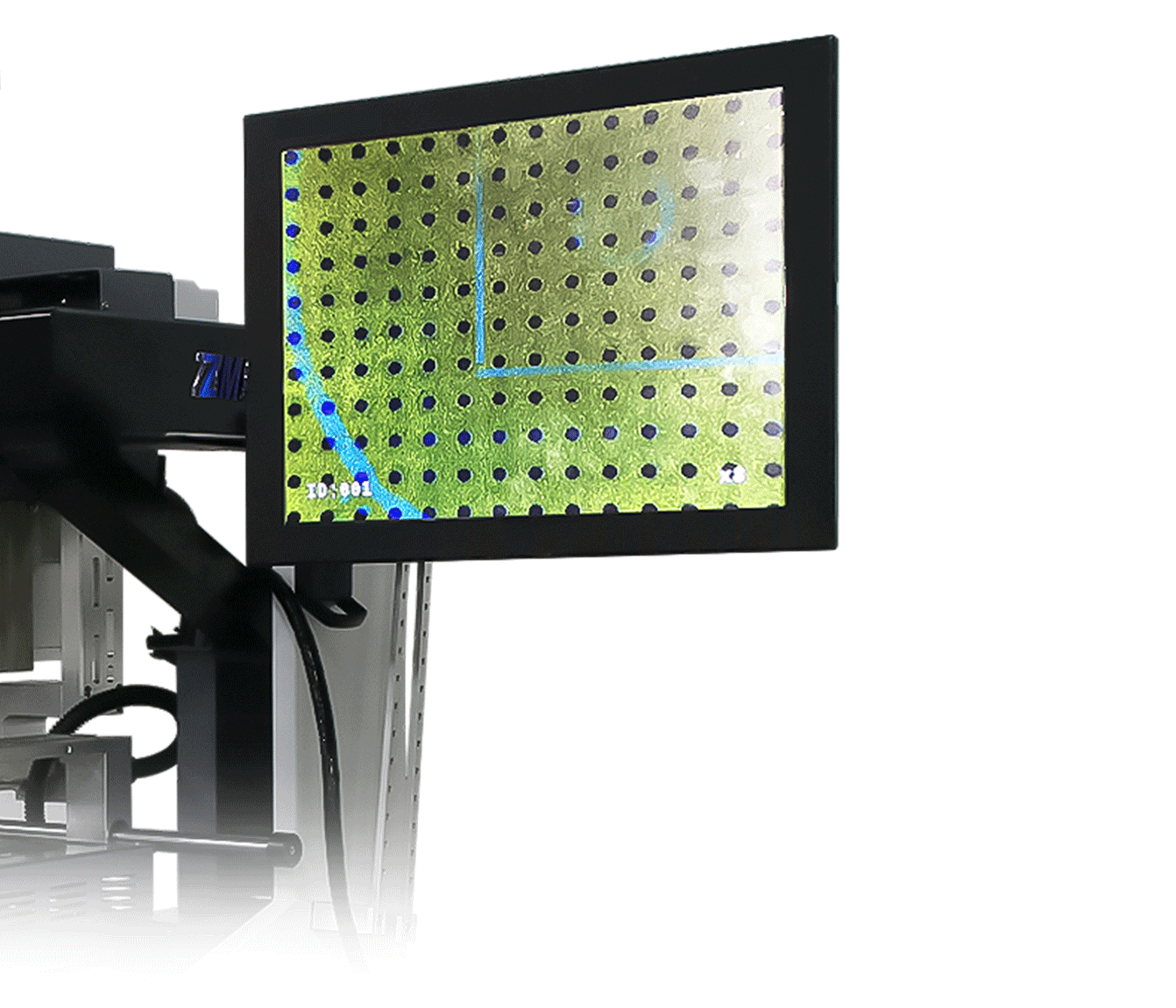

Split-Vision Technology: Features a high-resolution color CCD optical system with split-vision, zoom, and micro-adjustment capabilities.

Crystal Clear Visuals: Observe the perfect alignment of BGA solder balls and PCB pads on the 15-inch HD display.

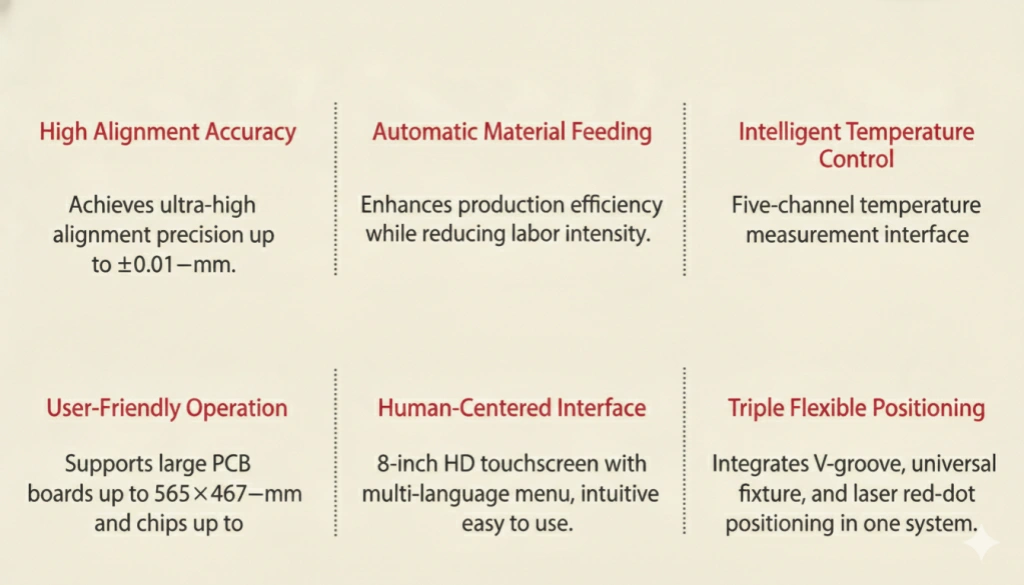

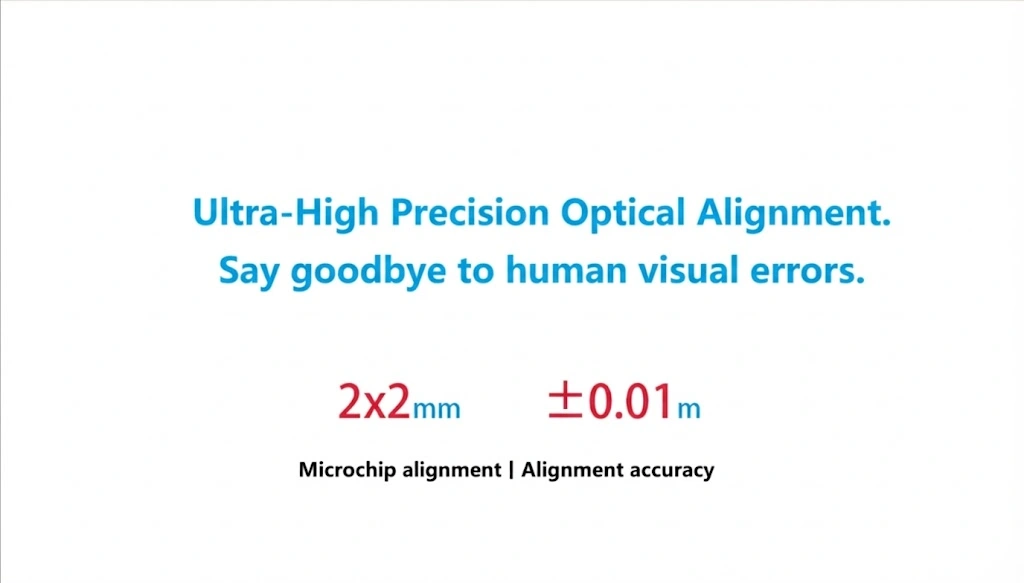

Extreme Precision: Achieves placement accuracy of ±0.01mm, easily handling components with pitch as small as 0.2mm.

Hybrid Power: Top Hot Air + Bottom Hot Air + Large Area Bottom IR Preheating. This hybrid design prevents the "popcorn effect" and PCB deformation.

Server Board Ready: The large carbon fiber infrared preheating area ensures uniform heat distribution, crucial for reworking large, multi-layer server motherboards.

Closed-Loop Control: High-precision K-type thermocouples monitor temperature in real-time, keeping deviation within ±1℃ of your set profile.

3-in-1 Automation: Automatically Desolder, Mount, and Solder with a single button press.

Pressure Sensing Protection: The mounting head is equipped with a sensitive pressure sensor. It automatically detects the PCB height and stops immediately upon contact to prevent crushing the chip.

Laser Positioning: A red laser pointer helps operators quickly position the PCB for faster batch processing.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know some different types of BGA repair machines and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

The ZM-R7830A is the industry standard for reworking various encapsulation types:

Components: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, and Micro-SMD components (down to 01005).

Industries: Cloud Server Repair, 5G Telecommunications, Automotive Electronics (ECU), Aerospace, and Mobile Device Refurbishing.

| Model No. | R7830A |

| Power Supply | AC380V±10% 50/60HZ |

| Power | 7.15KW(Max), Top heater(1.45KW) Bottom heater (1.2KW), IR Preheater (4KW), Other(0.5KW) |

| PCB Size | 565*467mm(Max); 6*6mm(Min) |

| BGA Chip Size | 80*80mm(Max); 2*2mm(Min) |

| IR Heater Size | 500*380mm |

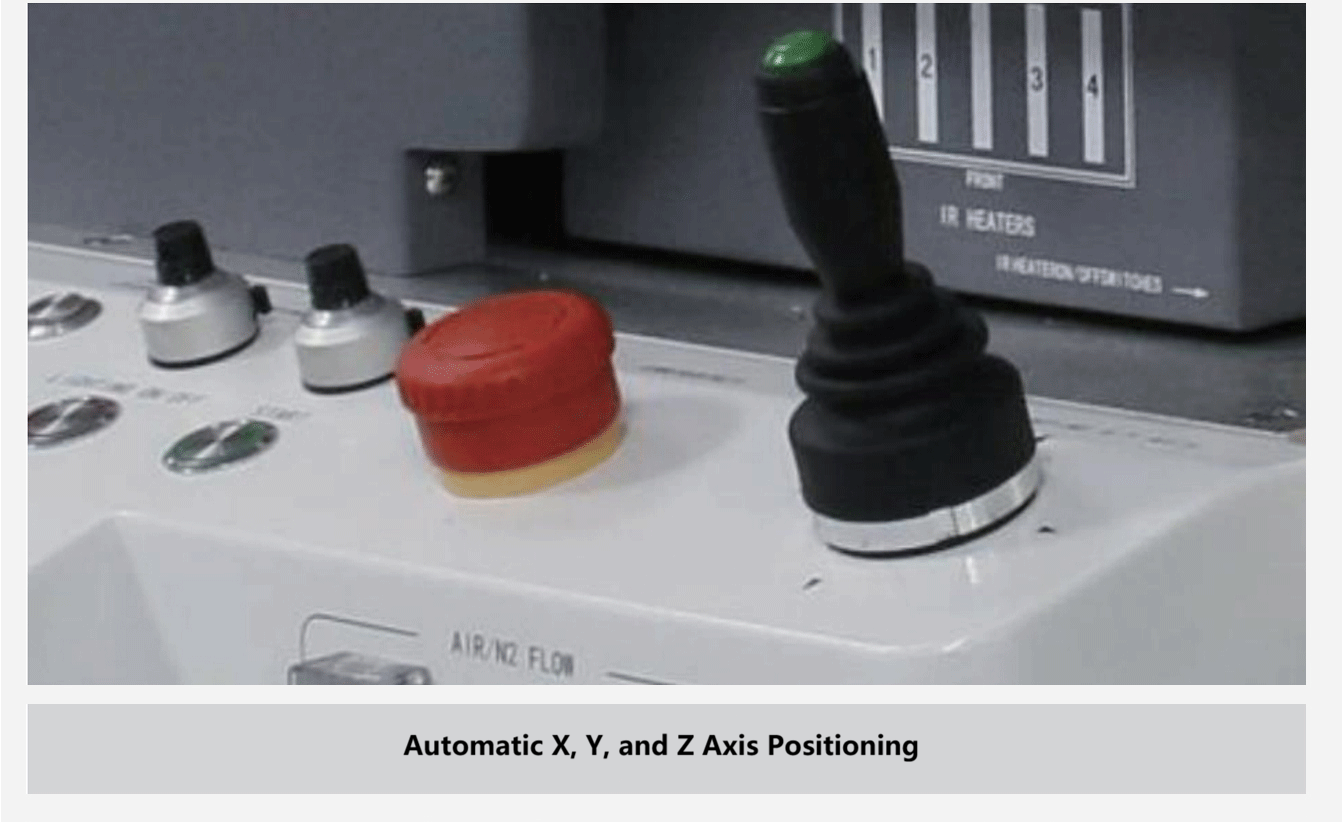

| Motion Control | X/Y/Z |

| Temperature Sensor | 5 Pcs |

| Operation Method | 8" HD touch panel |

| Control System | Panasonic PLC + Temperature control module |

| Display System | 15" HD industrial display ( 1080P 16:9) |

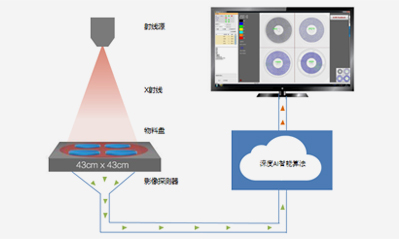

| Alignment System | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator |

| Vacuum Adsorption | Automatic |

| Alignment Accuracy | ±0.01mm |

| Temperature Control | K-type thermocouple closed-loop control with accuracy up to ±1℃ |

| Feeding Device | Yes |

| Positioning | V-groove with universal fixture |

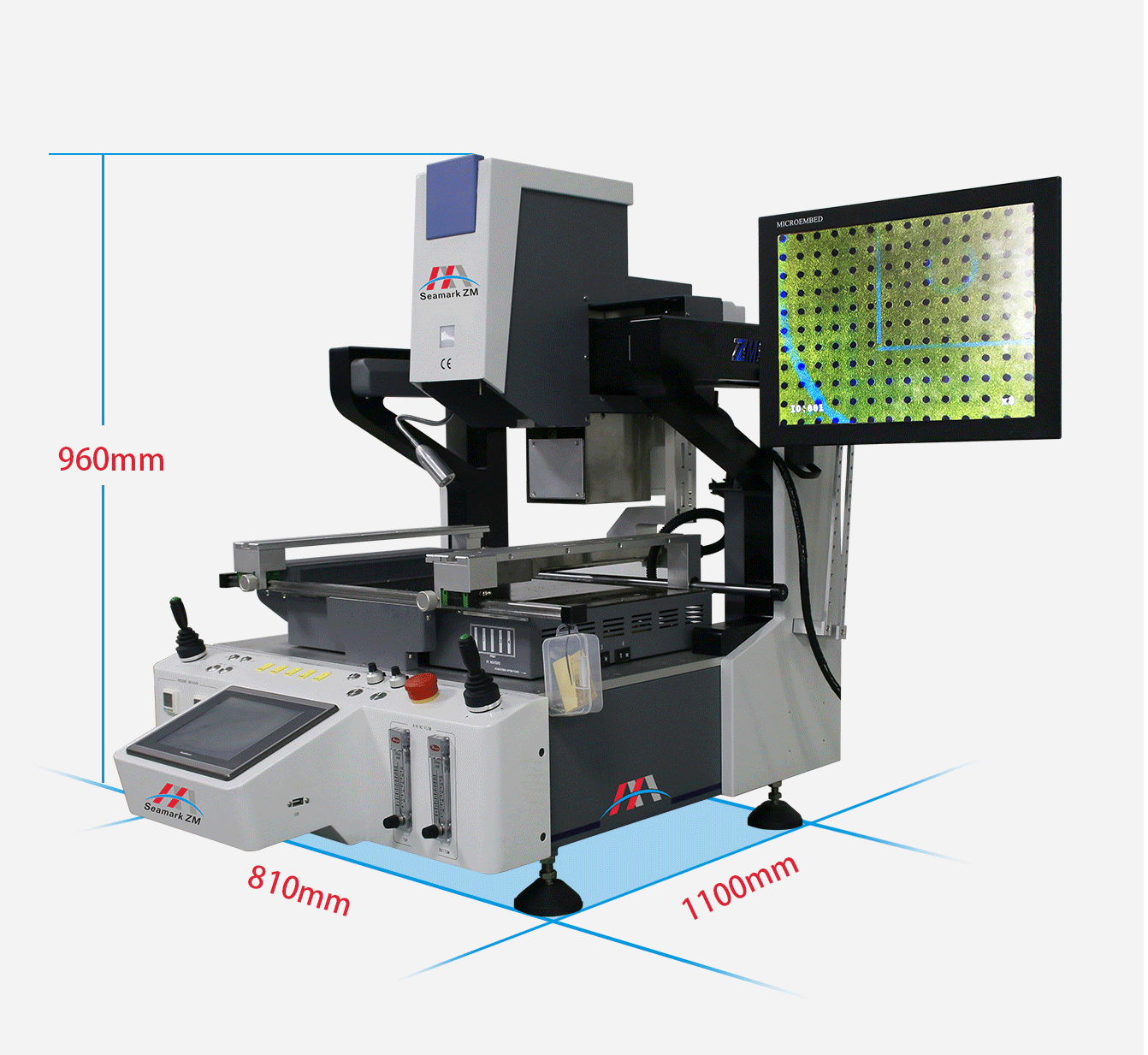

| Dimensions | L810*W1100*H960mm |

| Weight | 151KG |

The system features an intuitive graphical interface with an 8-inch touchscreen, joystick control, and multi-language support, allowing seamless switching between Chinese and English.

Combined with joystick-based agile X/Y/Z axis control, critical processes such as alignment and calibration become simple and intuitive, significantly reducing the training cycle.

An integrated automatic feeding mechanism frees operators from repetitive manual tasks, boosting overall production efficiency by over 30%.

The ZM R7830A alignment system integrates beam-splitting, zoom-in/zoom-out, and fine adjustment functions, and is equipped with automatic color difference recognition and brightness adjustment.

It automatically optimizes imaging in both high-brightness and dark-field conditions, clearly revealing solder balls and pads, significantly reducing dependence on operator experience and visual judgment.

The system integrates multiple functions including top heating, bottom heating, a preheating zone, and a feeding mechanism, while maintaining a compact overall size of only L810 × W1100 × H960 mm and a weight of 151 kg.

It innovatively combines V-grooves, universal fixtures, and laser red-dot positioning. Whether for standard rectangular boards, irregular-shaped boards, or flexible PCBs, an optimal fixing solution can be achieved, effectively preventing damage to board edges or surface-mounted components.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru