Trusted by Tier 1 EMS Leaders

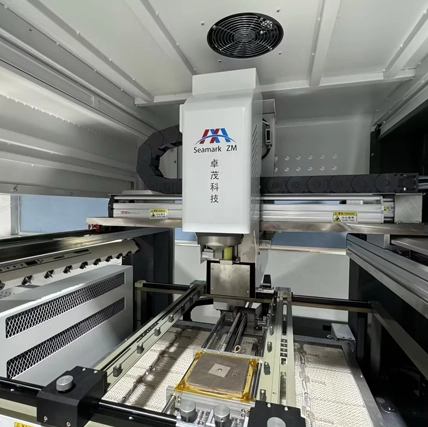

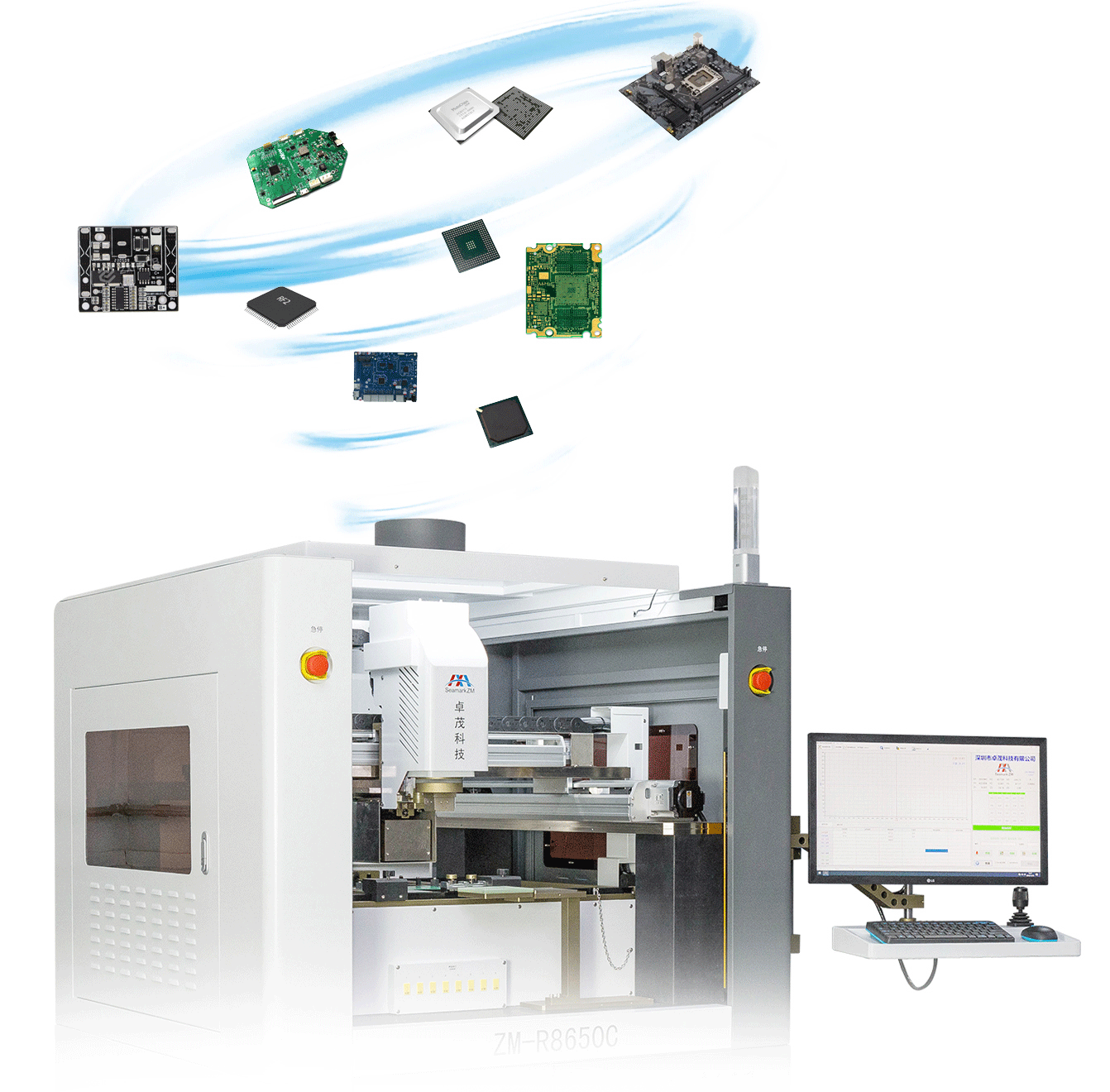

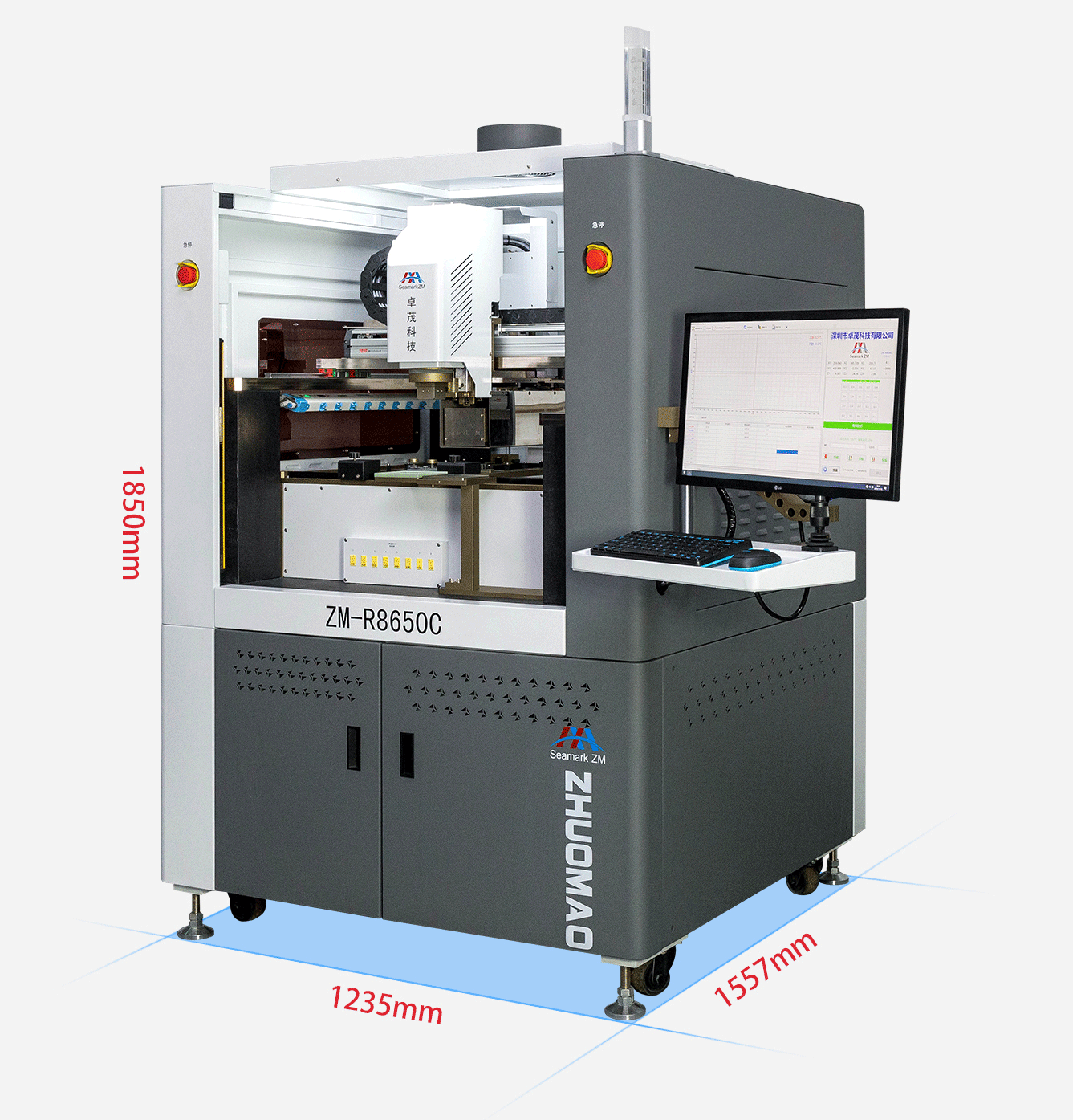

R8650C fully automatic BGA rework station is a fully automatic visual alignment BGA rework station. This BGA repair station can be used as an automated desoldering machine and is suitable for automatic visual placement of various chip devices on large PCB boards (such as 5G communication boards), automatic welding, and automatic PCB soldering station. This automatic SMD soldering rework station machine can be combined with SAP/ERP to realize the software linkup (optional), and to realize the temperature curve sub-board with S/N as the retroactive condition.

As a responsible BGA rework station supplier in China, Seamark promises to provide our best Automatic Soldering Machine at a reasonable price.

-High Precision (±0.01mm)

-Fully Automatic (Desoldering/Mounting)

-Over 99% Rework Success Rate

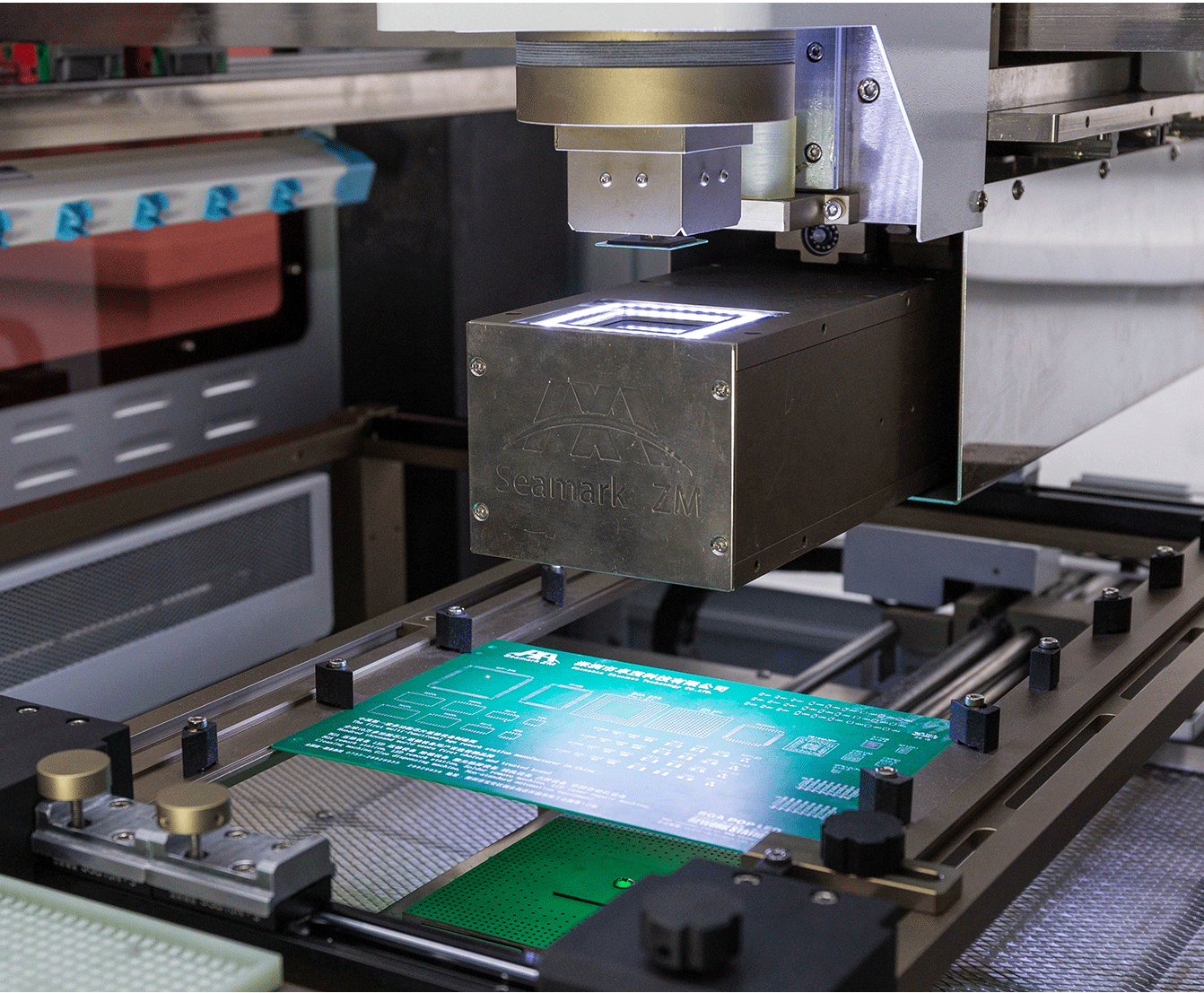

Achieves fully automatic optical mounting and desoldering. Optional software docking with SAP/ERP systems is available. Features temperature profile analysis using S/N (Serial Number) for traceability.

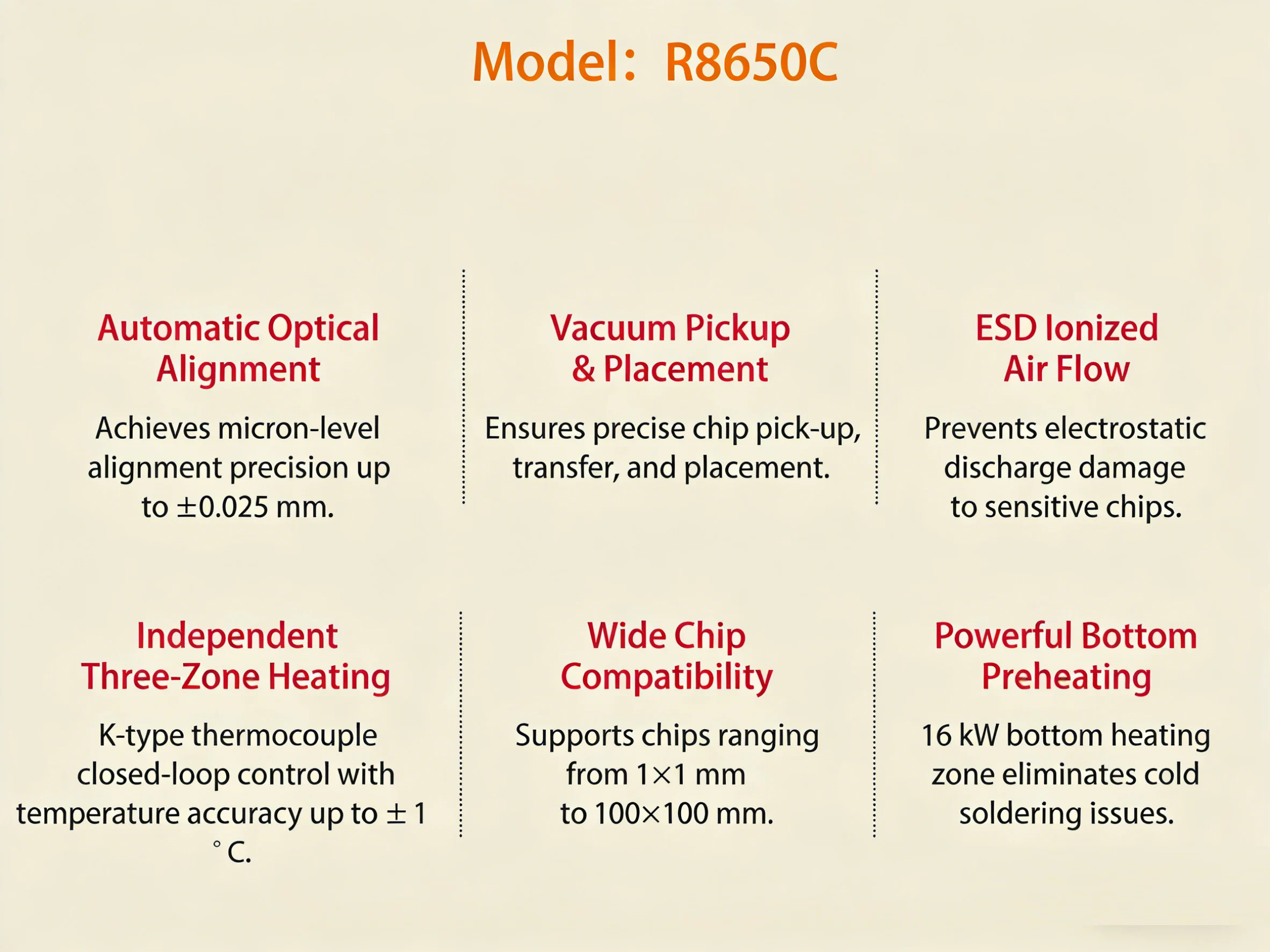

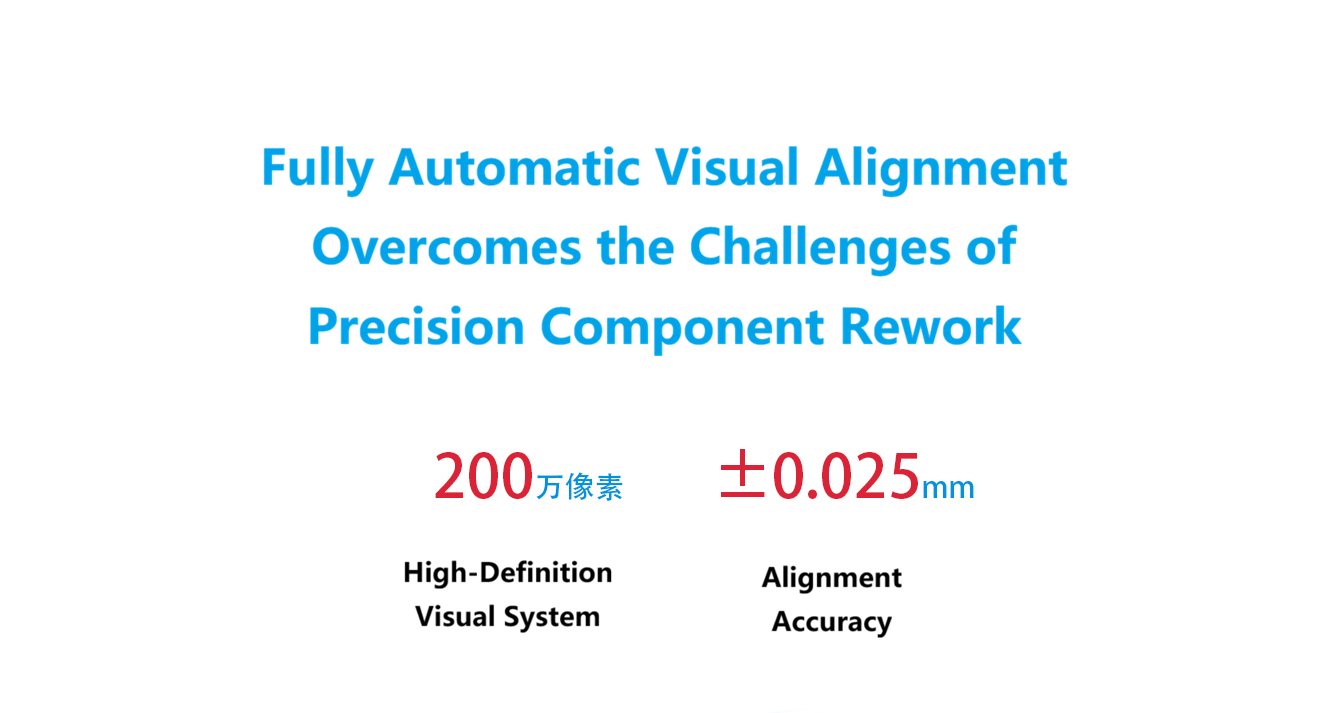

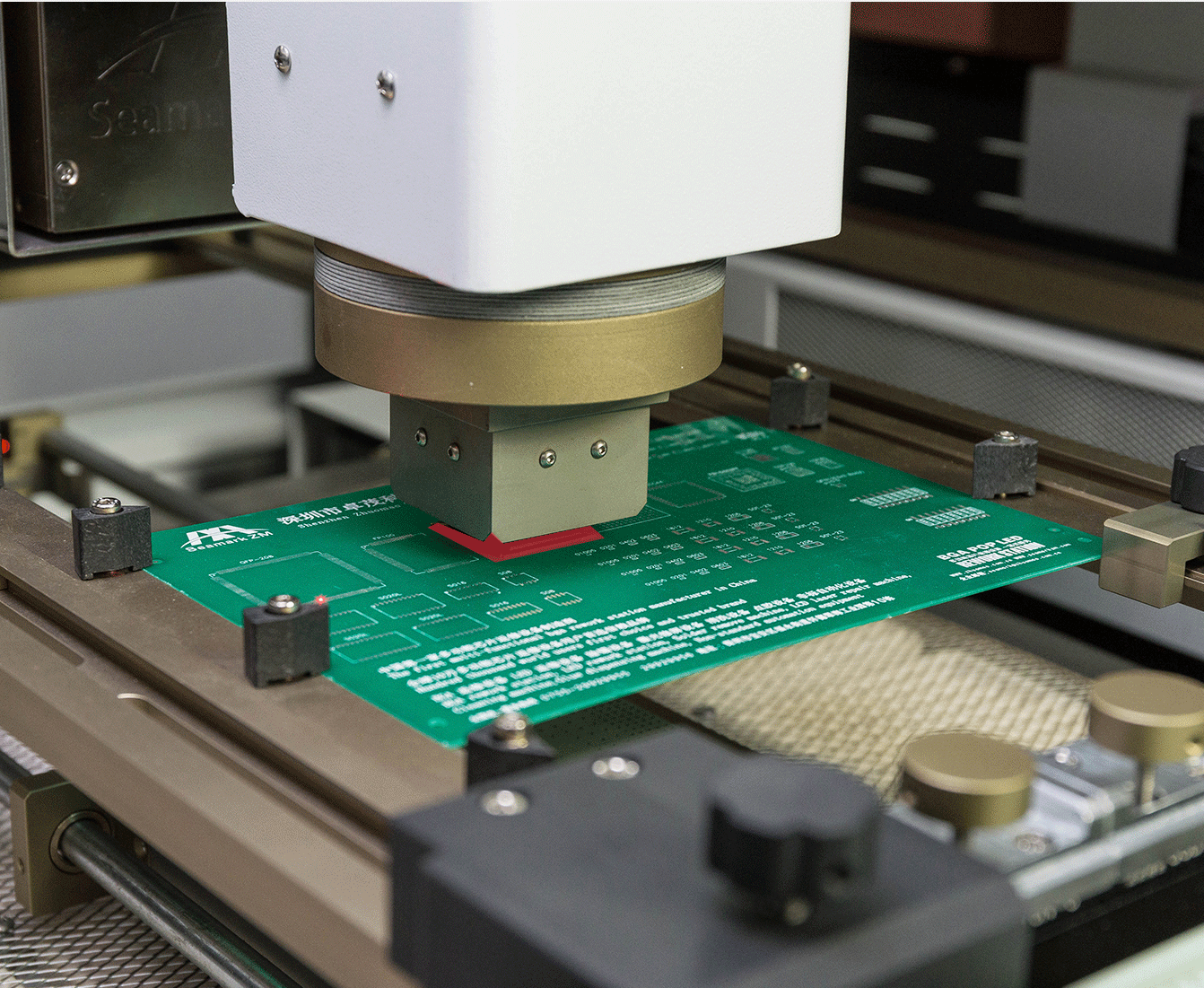

Alignment accuracy reaches ±0.025mm. High-precision K-type thermocouples ensure temperature accuracy within ±1℃. Utilizes dynamic PID multi-loop closed-loop control and a selective reflow soldering process.

Seamark's self-developed software system enables fast positioning and generates stable temperature profiles (with built-in profile analysis function). The operation and settings are user-friendly.

The top and bottom zones utilize convection hot air heating. The bottom zone features a large-area heating wire layout, making it suitable for reworking large BGAs. The infrared preheating zone uses German-imported medium-wave ceramic infrared heating plates.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know the automatic BGA rework station and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

| Model No. | ZM-R8650C |

| Power Supply | AC380V±10% 50/60HZ |

| Power | Total power 22KW Upper temperature zone (2KW) Lower temperature zone (2KW) Preheating temperature zone(16KW) Other power(2KW) |

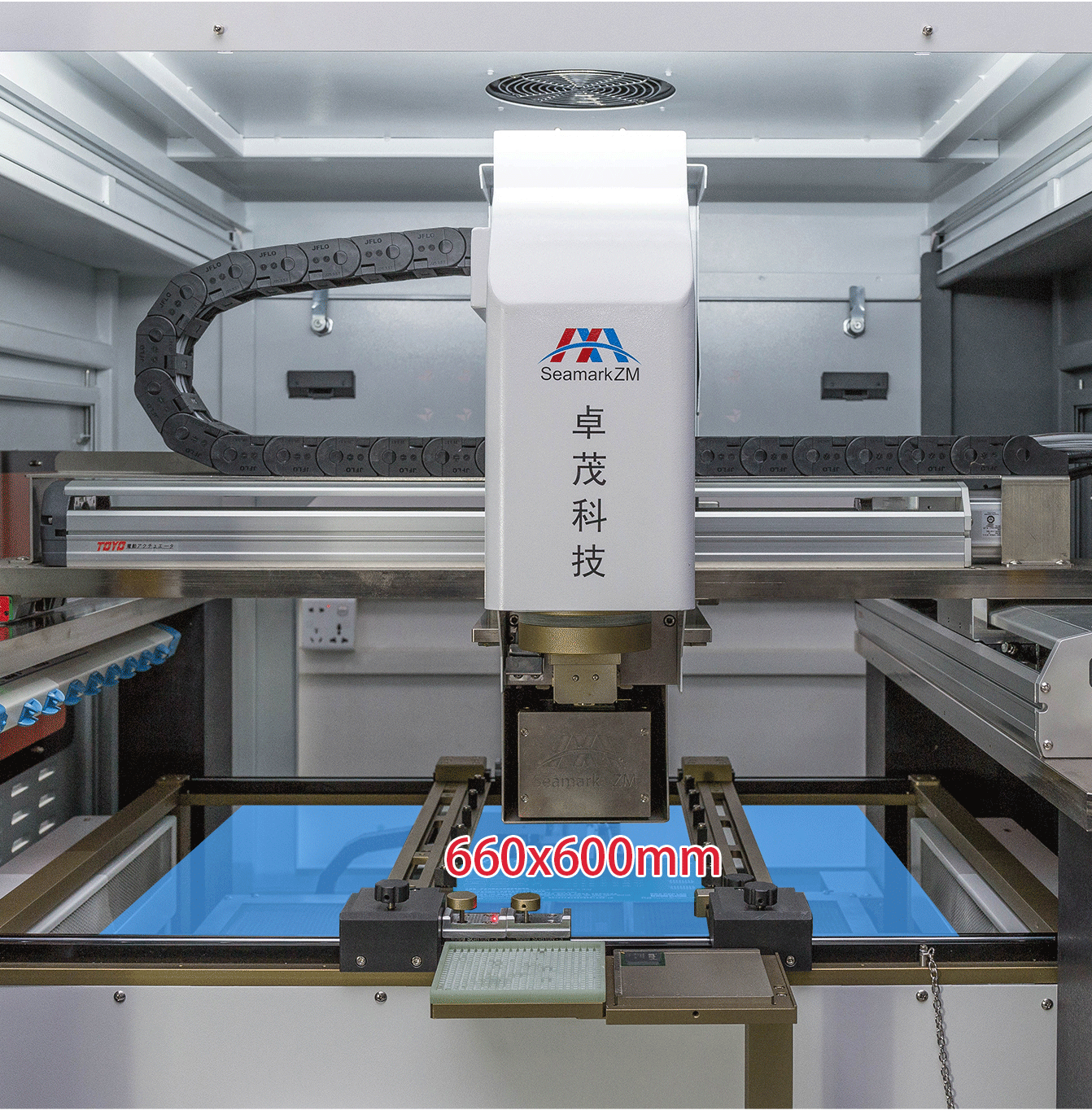

| PCB Size | 660×600mm (Max); 10×10mm (Min) |

| BGA Chip Size | 100×100mm (Max); 1×1mm (Min) |

| IR Temp. Zone Size | 645×524mm |

| Motion Control | X/Y/Z |

| External Temp. Sensor | 8PCS |

| Control System | Industrial PC + Servo Motion Control System |

| Display System | 24" HD Monitor |

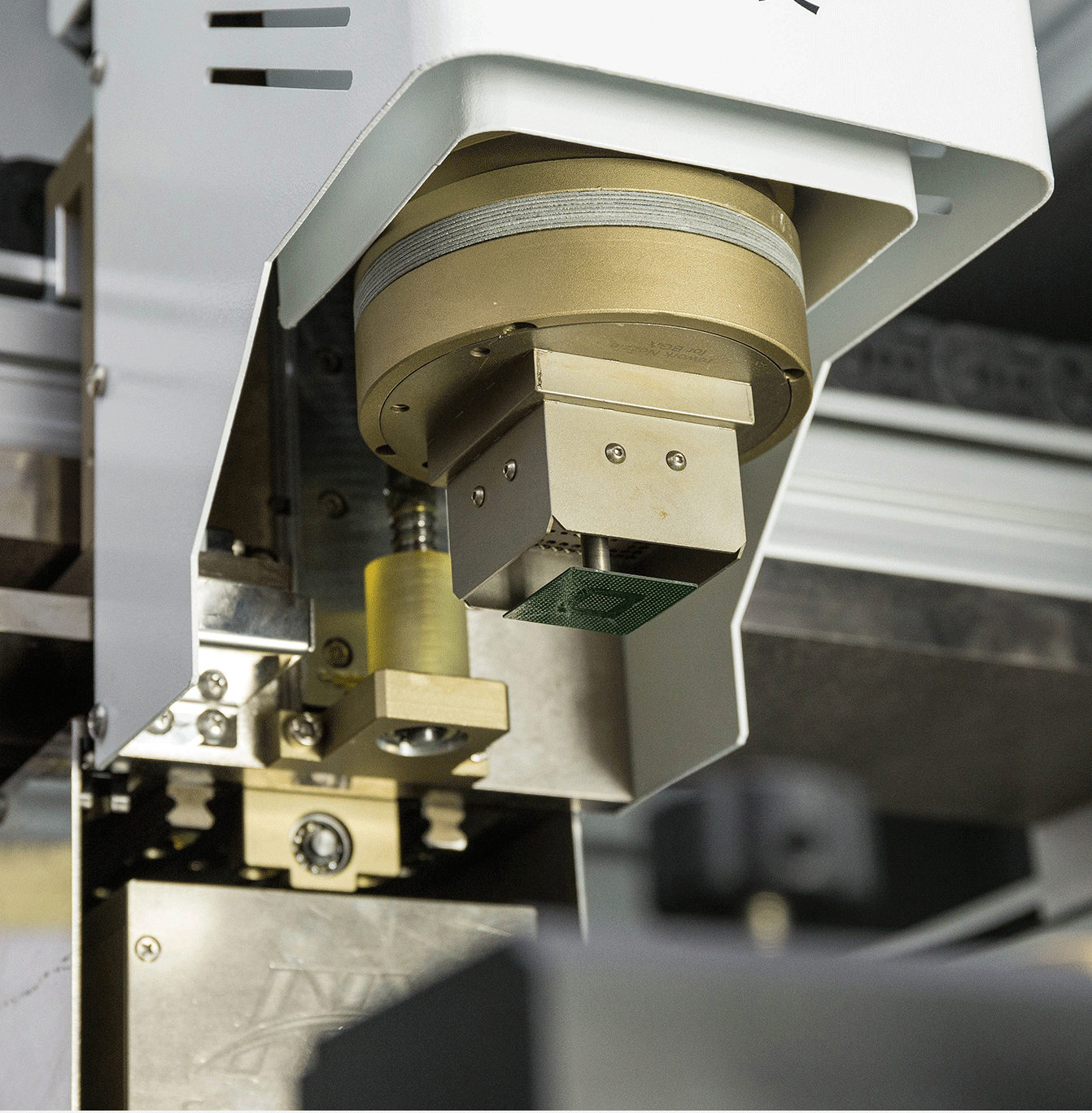

| Alignment System | 2 Million Pixels Optical Vision Alignment System |

| Vacuum Adsorption | Fully Automatic |

| Alignment Accuracy | ±0.025mm |

| Temp. Control | K-type thermocouple closed-loop control, independent temperature control for each unit, precision within ±1℃ |

| Feeding Device | Semi-automatic |

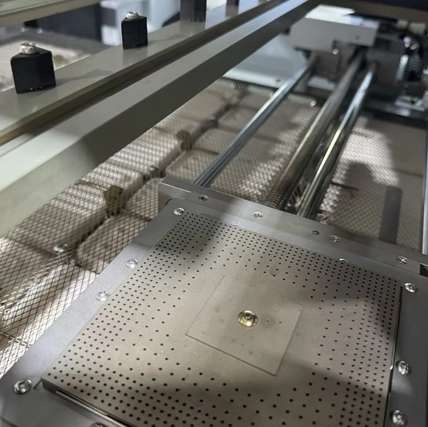

| Positioning | L-groove and Universal Fixture (Customizable for irregular fixtures) |

| Dimensions | L1235×W1557×H1850mm |

| Net Weight | 993.5 KG |

Seamark ZM R8650C is equipped with a 2-megapixel high-definition vision system and a precision servo platform, achieving micron-level alignment accuracy of 0.025 mm. From recognition and positioning to component placement and soldering/removal, the entire process is fully automated, eliminating reliance on operator experience or manual skill. Even beginners can easily achieve perfect chip alignment, significantly improving rework efficiency and first-pass success rate.

The system integrates upper, lower, and preheating zones, each independently controlled by a K-type thermocouple in a closed-loop system, achieving a temperature control accuracy of ±1°C. It can precisely simulate reflow soldering profiles, providing optimal thermal distribution for chips and PCBs of various sizes, effectively preventing thermal damage and ensuring reliable solder connections.

Seamark ZM R8650C supports PCB sizes up to 660×600mm, with an IR heating zone covering 640×520mm, providing ample rework space for large industrial control boards, server motherboards, and 5G base station boards. Equipped with 8 temperature measurement interfaces, it can record and analyze complete temperature profiles in real time, enabling standardized process parameter management and full data traceability throughout the rework process.

The system supports rework of components ranging from ultra-small devices as small as 1 × 1 mm to large modules up to 100 × 100 mm.

It is equipped with a fully automatic vacuum pick-and-place system, enabling precise component pickup, transfer, and placement.

The entire process is smooth, stable, and highly reliable, effectively eliminating the low efficiency, poor consistency, and risk of physical damage to components associated with manual handling.

This automation not only reduces labor dependency but also ensures the safety and integrity of high-value electronic components.

The Seamark ZM R8650C features a full ESD-protection design and is equipped with an integrated ionizing air blower.

Before operation, it effectively neutralizes electrostatic charges on PCBs and electronic components, providing comprehensive protection for high-value BGA chips and printed circuit boards.

This all-round ESD control significantly reduces the risk of electrostatic damage and improves overall process reliability.

The equipment is equipped with L-shaped slots and universal fixtures, and supports customization for irregular shapes, enabling fast changeover and stable fixation of various PCBs. Combined with a 16 kW bottom preheating zone, it provides sufficient and uniform bottom thermal compensation, rapidly raising the overall PCB temperature and ensuring that solder joints on large ground planes can fully reach reflow temperature, effectively eliminating cold solder joints.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru